There’s not much left of this project that “needs” done, but there’s always something else that “wants” done.

Sometimes that leads me to finding upgrades I didn’t know I wanted. The bike was running great. The weather was warming up and between the flooding storms and the very rare tornado going past the house, I managed to get out and enjoy the bike. But I kept hearing something… at idle that didn’t seem… right. Like a soft knock, but not a “this is gonna be expensive” knock.

After doing some research and talking to smarter people, I concluded that it was either a worn compensator or inner primary bearing. At first, I thought it was no big deal, then I saw how deep into the primary I had to go to get to the bearing and the dollar signs started adding up… If I’m gonna have it apart that much, I might as well upgrade this, but then I have to take apart that, so why not also change … cha-ching, cha-ching.

This next part may make some of the “elders” wince but I never really liked the look of the belt drive. The pulley just looked… clunky. It's big, it hides the wheel, and it just didn’t fit the bike as I thought it should. I thought a big 530 chain would be a cool look while adding more detail that is (much like me) just a little off from the mainstream.

The chains from yesteryear were problematic, required a lot of maintenance, and ruined millions of pairs of jeans. These “new” ones with O-rings, X-rings, alloys, and all the other upgrades made in the last 150 years aren’t the same as the ones your dad or grandpa had. I was sold on the idea of going with a chain, but finding one that was available and reliable was a bit of a struggle for a 6-Speed Twin Cam Softail. After some digging and a phone call, I ended up ordering a kit from Vulcan Engineering Company.

I knew as soon as I called them, this was the type of company I wanted to do business with. A true small business, everything made in-house. When I called, a gruff-sounding guy answered the phone. I stated I had some questions about the Softail chain conversion kit they offered. “Yeah, hang on a min,” then he set the phone down. While waiting, I could hear the unmistakable sound of CNC machines whirring, the pulsating sound of cutting tools turning metal stock into chips at a high rate of speed, and the sound of guys on the shop floor muttering about this and that.

Armed with the info I needed, I ordered a kit with a black sprocket and a black/chrome 530 sealed chain with a sprocket ratio that closely matched the factory belt drive. When it arrived, I was impressed to see the quality of the CNC pieces they had supplied. Everything about it seemed, well, “beefy.”

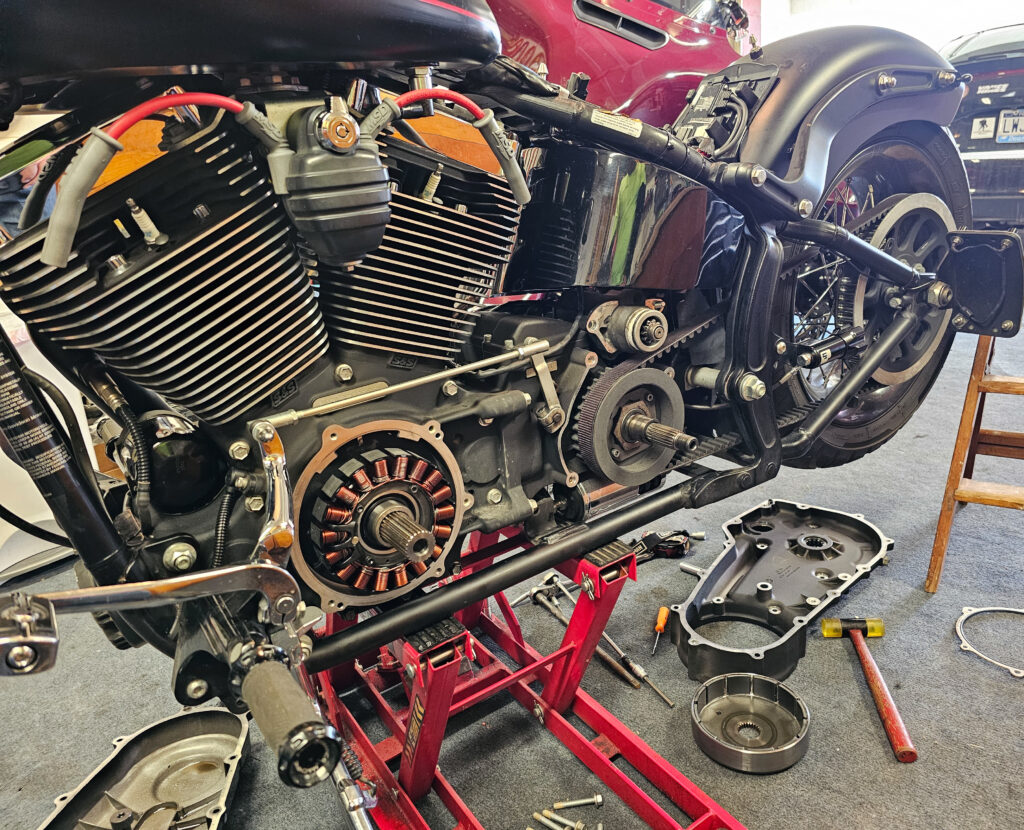

And so began the teardown, completely removing the inner and outer primary, compensator, clutch, and final drive. This, of course, took a lot longer than I had anticipated because I forgot to check for special tools I’d need to get everything apart. Once I sourced the tools, things went a bit smoother. The install went very well. Everything just fit. No messing around, fumbling, banging, or finagling. I was getting excited looking at it, absolutely loving the look, even if the primary wasn’t back on.

Since the primary was completely apart, it didn’t make much sense to put all the old parts back in, especially since the compensator was questionable. So, I looked to Baker Drivetrain to see what they offered. Not knowing exactly what I was looking for or what I needed, I gave them a call for some guidance.

The parts arrived, and I was like a kid at Christmas. I couldn’t wait to get it together and see how it rode. This was a surprise performance boost I wasn’t expecting that could change the attitude of the bike even more than I had already. Yet again, parts from a made-in-the-USA machine shop just have a different feel to them. Much to my surprise, Baker isn’t the giant manufacturing facility. It too is a small family-run operation making parts for bikers, by bikers.